Homes are dynamic and need to be treated as so. While finding and fixing thermal bypasses and air leaks may seem like the right thing to do, it can have deadly consequences if the combustion equipment in the home is not accounted for and tested prior to, during, and after repairs are made. The old saying one man's junk is another man's treasure could not ring more true considering that the thermal bypass or air leaks (junk) you're sealing might be providing all or some of the air (treasure) required for safe combustion of the fossil fuel appliances. Do not assume that sealed combustion appliances are safe either, as building pressures can easily overcome even the best designed appliances under the right (wrong) conditions.

When it comes to home construction, there is no such thing as too tight, actually the tighter the home the better. Remember though if you build or seal tight you must ventilate right for safe combustion. Mechanical ventilation is preferred to natural infiltration for several reasons, but primarily because it is controlled rather than a variable. Air is needed for combustion, dilution, and ventilation. A ventilation air test is needed after any repairs are made, and after mechanical ventilation is added. CO and stack O2 should be monitored prior to, during and after repairs are made. The question is “What do we need to know about safety and testing for CO and the measurements and tools needed to assure the safety of all involved?”.

Jim White, senior researcher with the Canadian Mortgage Housing Corporation, has a straightforward summary of this point: "Both people and houses need continuous ventilation to stay healthy, but natural ventilation does not provide continuous ventilation. Therefore, we need good mechanical ventilation. Good ventilation means balanced ventilation, and balanced ventilation works best in tight houses. Therefore, we need tight houses with good balanced ventilation systems in them. Anything less is just not good enough."

Tools Required for Testing

If you are considering or working in the building science, weatherization or HVAC industry, at minimum the following tools are required for your safety and to determine the safe operation of combustion appliances. While you may not be qualified to correct the combustion problems you may create, you must at minimum need to know if they exist. If you are not qualified or trained to make repairs to a heating system consult a qualified and trained HVAC contractor preferably who has been formally trained with dealing with issues of Carbon Monoxide (CO) and combustion testing.

Tools of the trade:

- Blower door to determine natural ventilation rates and aid in identifying thermal bypasses and points of air infiltration.

- Personal CO meter for your safety

- Combustion Analyzer (with CO and O2) for measuring and documenting ambient CO levels CO AirFree (COAF) levels or appliances, COAF stack levels for furnaces and boilers, and draft.

- Draft Gauge (included in most combustion analyzers) to assure that minimum draft requirements are kept for all vented appliances.

CO (Carbon Monoxide)

All fossil fuel appliances including those burning natural gas, propane, fuel oil, bio-fuels kerosene, wood, wood pellets, or even corn can produce dangerous levels of combustion byproducts if not set to burn properly. During combustion, carbon in the fuel oxidizes through a series of reactions to form carbon dioxide (CO2). However, 100 percent conversion of carbon to CO2 is rarely achieved under field conditions and some carbon only oxidizes to the intermediate step, carbon monoxide or CO.

Carbon monoxide is a pollutant that is readily absorbed in the body and can impair the oxygen-carrying capacity of the blood (hemoglobin). Impairment of the body's hemoglobin results in less oxygen to the brain, heart, and tissues. Even short-term over exposure to carbon monoxide can be critical or fatal to people with heart and lung diseases, the young or the elderly. It may also cause headaches and dizziness and other significant medical problems in healthy people. Studies are now linking long term exposure to low levels of CO increased heart and other health problems especially among the young, elderly, and breathing compromised.

Ambient CO Testing and Personal CO meters

Enough cannot be said about the need for personal safety and CO. The fact that most first responders don Self Contained Breathing Apparatus (SCBA) when levels exceed 35ppm CO should be enough to convince you that low levels of CO can quickly become high levels as you move toward the source. Personal CO detection with an audible alarm set at or below 35ppm should be worn at all times on your person, preferably one like the testo 317-3 which does not need to be zeroed in ambient air. Because CO is a colorless odorless gas it can quickly overcome anyone, often mimicking flu like symptoms prompting the victim to sit down for a minute rather than to get out of the contaminated area. If ambient CO levels exceed 35 ppm (as low as 9 ppm in some jurisdictions) during testing, shut down (isolate the fuel source) the appliance immediately. If the appliance is out of arm’s length and cannot be immediately be shut down, the best thing to do is to evacuate the premises then ventilate, in that order. Shut off the fuel source outside the premises so you are not exposed to dangerous CO levels as you approach the appliance. Typically CO only enters the home and or is produced because the flue gasses cannot exit, so depressurization and draft problems are the first things you need to investigate.

COAF (Carbon Monoxide Air Free) Stack CO Testing

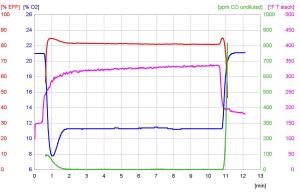

When testing in the stack, a combustion analyzer like the Testo 327 or 330 with a CO an O2 sensor is recommended. CO and O2 levels should remain stable. CO levels should not exceed 400 ppm COAF at anytime during operation and typically appliances should operate below 50 ppm COAF. The graph below (done with a Testo 330 equipped with EasyHeat PC software) shows how a typical combustion appliance should operate.

Look closely at the blue line, the O2 soon after light off stabilizes, and the COAF (ppm CO undiluted, the green line) operates close to 0 ppm during operation. The rising COAF at shutdown in this case is only seen due to the rising O2 and its affect on the COAF calculation. COAF and O2 both remain stable during operation of the burner and during the ventilation air testing process.

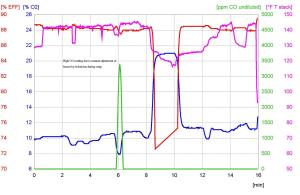

In the graph right, a typical burner plagued by combustion air problems is shown. As can be seen, the undiluted CO (COAF) was stable at 0 ppm CO indicating what appears to be an excellent operating characteristic. The telltale issue to operational problems can be seen in the instability of the O2 during operation. As can be seen from the graph, when the O2 dropped below 8% in this case the COAF went from 0 to 3500 ppm COAF almost instantaneously. Due rapidly rising CO the technician quickly pulled the probe to avoid damage to the CO sensor through saturation so the actual levels might have been considerably higher. This graph shows why a combustion analyzer and not a single gas CO meter is required for combustion testing as a rising CO or a dropping O2 both indicate potential CO problems.

In the graph right, a typical burner plagued by combustion air problems is shown. As can be seen, the undiluted CO (COAF) was stable at 0 ppm CO indicating what appears to be an excellent operating characteristic. The telltale issue to operational problems can be seen in the instability of the O2 during operation. As can be seen from the graph, when the O2 dropped below 8% in this case the COAF went from 0 to 3500 ppm COAF almost instantaneously. Due rapidly rising CO the technician quickly pulled the probe to avoid damage to the CO sensor through saturation so the actual levels might have been considerably higher. This graph shows why a combustion analyzer and not a single gas CO meter is required for combustion testing as a rising CO or a dropping O2 both indicate potential CO problems.Carbon monoxide is typically measured in parts per million (PPM); the number of CO molecules present in a million molecules of air.

CO is also measured and referenced as CO Air Free or ppm CO undiluted. This is a unit of measurement designed to compensate for the excess air to the burner and is only used to express CO levels in a flue gas sample as opposed to ambient air testing.

Because CO can be diluted by excess air, a COAF air free measurement is needed for an apple to apples comparison of equipment operation. A COAF measurement requires an O2 sensor and requires a two gas combustion analyzer for testing. Simply put, the COAF measurement is a standard for stack and appliance CO measurements. COAF readings should always be below 400 ppm and in reality COAF readings over 50 ppm indicate combustion problems. Typical industry standards dictate no burner be left in operation with levels over 100 ppm even though the ANSI standard is 400 PPM COAF. Levels below 50 ppm are easily achievable.

In today's equipment, high levels of carbon monoxide emissions primarily result from combustion dilution and ventilation air problems and or incomplete combustion due to poor burner maintenance or firing conditions. Examples would include an improper air-to-fuel ratio or possibly a misaligned burner.

No US standards exist for CO levels in indoor air. The U.S. National Ambient Air Quality Standards for outdoor air are 9 ppm (40,000 micrograms per cubic meter) for 8 hours, and 35 ppm for 1 hour (time weighted).

No CO (0 ppm) is the best level in the home. This cannot always be achieved due to smokers in the home and/or appliances like stoves or unvented space heaters that produce small but acceptable levels of CO during operation. Even an operating electric ovens will produce levels of CO as the Carbon in the food residue is oxidized. When CO is present in the home, the source should be determined and corrective action taken if required. The goal is to assure occupant safety and minimize the occupants’ exposure.

The local authority having jurisdiction should be consulted when determining the maximum safe level allowed in the home before shutting down the appliance and or making it inoperable. An appliance with rising CO or dropping O2 should always be shut down no matter how low CO production is at the time of testing. Rising CO problems are usually the result of improper venting and/or lack of combustion air, and a dropping O2 in the stack is a tell tale sign that combustion problems are imminent when the oxygen levels are no longer sufficient to support proper combustion.

Ambient CO Limits (Recommended)

0 ppm Desirable level of CO in a home

1-9 ppm Acceptable short term levels within a home. If there are no smokers, investigation is recommended. These levels will be measured above outdoor ambient levels in most cases because the CO instrument has been zeroed in outdoor air.

10-35 ppm Advise occupants, check for symptoms, (slight headache, tiredness, dizziness, and nausea or flu like symptoms.) check all unvented and vented appliances, including the furnace hot water tank and or boiler, check for other sources including attached garages or small engine operation

50 ppm Maximum concentration for continuous exposure in any 8 hour period. (National Occupational standard)

36-99 ppm Recommend fresh air, check for symptoms, ventilate the space, recommend medical attention

100+ PPM Evacuate the home (including yourself!) and contact emergency medical services (911). Do not attempt to ventilate the space. Short-term exposure to these levels can cause permanent physical damage.

400 ppm Frontal headaches within 1-2 hours life threatening in 3 hours

800 ppm Nausea and convulsions, death within 2 hours

1600 ppm Nausea within 20 minutes and death within one hour

12,800 ppm Death within 1-3 minutes

Maximum CO Levels in Equipment

Vented (Note CO reading must remain stable and are measured on an air-free basis)

- 400 ppm (CO-Air Free: CO-AF) Stack ANSI Z 21.1

- 100 ppm CO Stack recommended

ALWAYS FOLLOW REQUIREMENTS of AUTHORITY HAVING JURSIDICTION

Unvented appliances

- 30-50 ppm stable

- Less than 10 ppm recommended

- Ovens Less than 300 ppm (100-300 ppm) install CO detector if left in operation.

Draft

Appliances need to exhaust the byproducts of combustion outside the dwelling. This is accomplished through natural or forced draft. Air sealing a home can result in changes in draft characteristics that may be undesirable or dangerous. Depressurization of the CAZ (Combustion Air Zone) and the actual appliance draft need to be verified to fall within acceptable limits for outdoor air temperature as outlined in BPI and RESNET standards and or within limits outlined in the Testo Combustion Applications Guide. Again, local jurisdiction may have authority.

The moral of the story is: “If you find it and fix it, test it for combustion safety.” Finding problems is only the first part of fixing the problem. Don’t let your excitement for fixing air leaks get the best of you and hurt your clients.

REFERNCES

BPI Standards: www.BPI.org

RESNET Standards: www. RENET.us

Testo Combustion Applications Guide: www.testo.us/appguide

No comments:

Post a Comment